(SMC & BMC)

What is SMC?

SMC is the abbreviation of Sheet molding compound. The main raw materials are composed of glass fibers, unsaturated resin, low shrinkage additives, fillers and various additives. In the design of SMC molded products, it is necessary to determine the shape and structure of the product according to the application, quality requirements of the SMC product, the working condition of the load, and according to the actual molding production. Analysis are necessary to make the determined product structure meet the process requirements of molded manufacturing.

What is BMC?

BMC is the abbreviation of Bulk molding compounds, often called unsaturated polyester bulk molding compounds. The main raw materials are made of GF (chopped glass fiber), UP (unsaturated resin), (filler) and various additives mixed into a dough shape.

Advantages of SMC & BMC Manhole Covers

over the traditional Cast iron covers

load bearings.

Defects of other types:

- High Cost.

- Less Age.

- Very Heavy.

- Breakable, erosive and corrosion.

- Can be stolen and recycled. Electrical Conductivity and static charges.

- Noise pollution and vibration transmission which lead to an effect on neighboring parts so requires periodic maintenance.

SMC

SMC is a polymer composite material, mainly composed of thermosetting resin, mineral filler and glass fiber reinforced material. The resins used are usually unsaturated polyester. Because the material is in sheet form, it is called Sheet Molding compound or SMC.

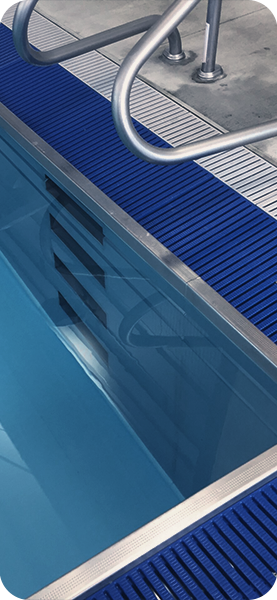

Various Applications

Unique Advantages of SMC Manhole Covers

over other covers:

1. Higher in quality.

2. Longer life time; the service life can reach more than 50 years. Normal use in the range of -40°C to 100°C, the service life is more than 5-10 years longer than ductile iron manhole covers, and more than 30 years longer than steel fiber manhole covers and BMC manhole covers.

3. Much higher strength. Generally speaking, other composite manhole covers does not endure heavy load-bearing requirements, and is usually used in places such as residential green belts, and in roads with normal types of vehicles, while SMC manhole covers in addition to the previous applications can be used in heavy load-bearing applications as in airports.

4. In all applications the overall performance of SMC manhole covers is much better than other covers. SMC manhole covers is widely used in important traffic roads, airports, gas stations, telecommunications, communications, gas piping networks drinking water and sanitation piping networks.

5. Provides more flexibility.

6. Sturdy structure, suitable for various complicated traffic sections and construction sections.

7. Often, ordinary manhole covers are easy to be damaged and perforated, which will bring great maintenance costs to the operation and maintenance of subsequent projects. SMC manhole covers have excellent pressure resistance and wear resistance, and are not easily damaged under various complicated conditions.

8. The BMC manhole cover has a cross rebar inside the compound material, which is used to enhance its strength. However, cracks may occur between the rebar and the surrounding material, which will never happen to the SMC manhole cover. Therefore, the SMC manhole cover reduces the risk of cracks.

03.

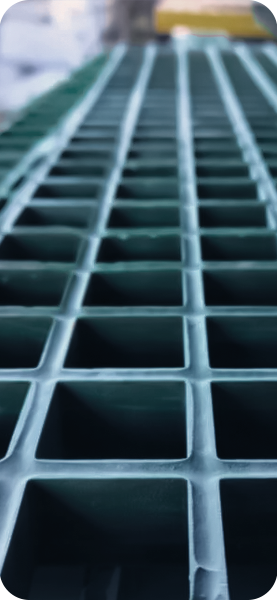

Why SMC Manhole Covers are superior to BMC covers?

The most premium feature of SMC composite manhole covers is due to the regular and uniform distribution of the fiberglass reinforcing material in all parts of the sheets produced which leads to a completely homogeneous material with very high strength covers in comparison to BMC covers in addition to higher quality longer life period.